Klaster Trading House delivers various types of heat-exchange equipment. The heat exchanger apparatuses are one of the main kinds of equipment at oil and gas production and chemical facilities. The heat exchangers are designed for transmission of heat from one medium to another. The recuperative heat exchangers allow saving energy resources and increasing efficiency of operation of an industrial enterprise on the whole.

Klaster Trading House is offering the following types of heat exchanger :

• Plate heat exchangers

o knock-down

o welded

• Spiral heat exchangers

• Shell-and-tube heat exchangers

• Submersible heat exchangers

The plate knock-down heat exchangers are widely used due to their simple design and low cost. These heat exchangers are designed for cooling different media at working pressures of up to 4.0 MPa (g.) and temperatures from minus 25°С to plus 200°С.

The welded heat exchangers are used for handling liquids, gases and two-phase media at pressures of up to 10.0 MPa and temperatures from minus 50°С to plus 500°С. They are made of different materials, including corrosion-resistant steel.

The spiral heat exchangers are made in the form of a cylindrical apparatus inside of which there is a pipe with two plates wound around it. They are characterized by the largest heat-exchange surface area and the minimum overall dimensions and allow reducing temperature difference between the medium to be heated and the heating medium to 2°С. The spiral heat exchangers are used at working pressures of up to 6.0 MPa and temperatures from minus 100°С to plus 500°С.

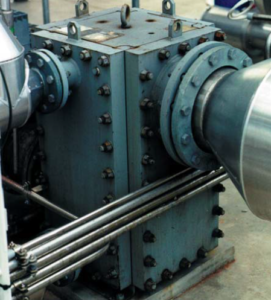

The shell-and-tube heat exchangers ensure transmission of heat through a warm metal partition wall. In the recuperative heat exchangers the heat carrier and the medium to be heated do not get in contact with each other. The pressure range within which the shell-and-tube heat exchangers are used is not limited, but does not exceed, as a rule, 10.0 MPa. The operating temperature limits depend only on their design in accordance with the requirements of the TEMA standard.

The design of the submersible heat exchangers consists of a tubular coil immersed in a tank with liquid. The best way of using such heat exchangers is for heating media to boiling temperature and with a lot of mechanical particles. The submersible heat exchangers can be either rectangular or cylindrical in shape.